Chassis meet body

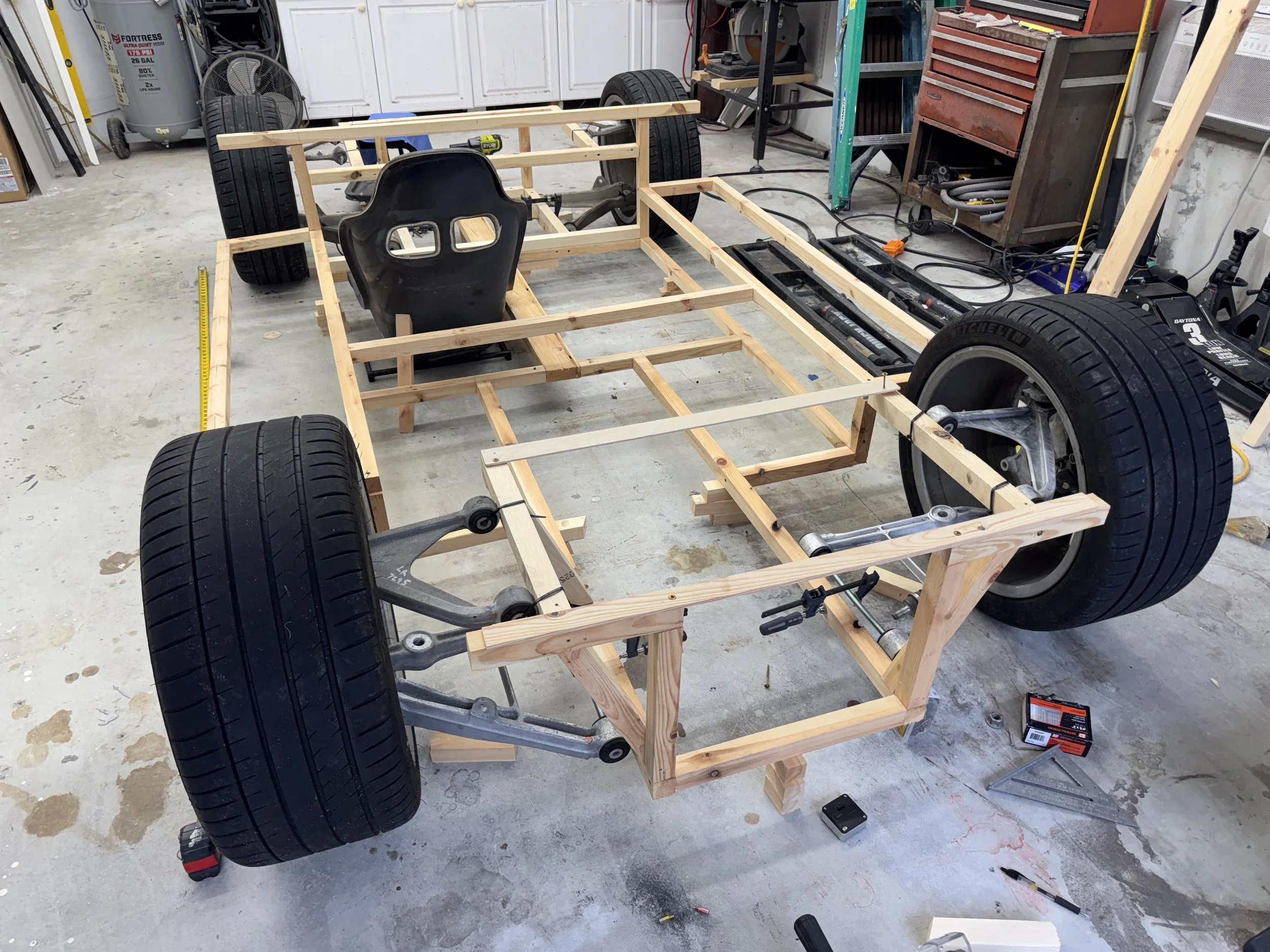

Once the body arrived, the next step was clear: I needed a foundation. For weeks leading up to delivery, I’d been sketching, modeling, and refining a temporary wooden frame to support the body. It wasn’t meant to be the final chassis — not yet — but rather a full-scale mockup that would let me test geometry, clearances, and proportions before committing to steel.

Every piece of lumber was cut and placed with intention, designed to mirror the structural layout I had in mind for the eventual space-frame chassis. I studied dozens of other GT40, Lola, and mid-engine chassis designs, pulling ideas from each — triangulation patterns, suspension pick-up point layouts, and load paths — then blending them into something that felt uniquely mine.

When the shell was finally lifted from its crate, it was surreal to lower it onto the frame I’d built by hand. The body settled perfectly into place — the stance, proportions, and symmetry were everything I had hoped for. Even though it was temporary, that moment made the project feel real for the first time.

The wooden frame isn’t just a placeholder; it’s a roadmap. It allows me to visualize exactly how the space-frame will integrate with the body, drivetrain, and suspension. Every measurement I take from it — every bracket, curve, and mounting point — will be translated into steel.

It’s the first physical link between imagination and execution. Soon, this wooden skeleton will give way to a fully welded steel chassis, FEA-validated for strength and stiffness, and the real build will begin.